Solder is the glue of electronic circuits. In addition to a permanent mechanical connection, solder provides an electrical connection. Not too much unlike glue solder combines two separate metal pieces with a bonding material. In this case, the bonding material is a metal or allow with a relatively low melting point.

When soldering together a circuit, the quality of the solder joint is crucial. Most people probably recognize the need for a high-quality soldering iron, like the FX-888D from Hakko, but about the other tools?

Building a modular soldering station is just as critical to making good solder joints as the actual solder itself.

When you look at my electronics bench, you can probably tell it’s a desk from Ikea. Why? I live in an apartment where the room with my electronics workbench triples as my office and my storage room. In other words, I don’t have much space. Which means, there is no dedicated soldering station in on my bench—a surprise to many.

Having a solid soldering station is critical. For me, and I suspect many of you, solid isn’t enough. You also need a modular soldering station. Throw away your “3rd Hand” cheap soldering tool and upgrade using these options available from PanaVise.

To be clear, this post isn’t meant to be a PanaVise ad. They just make some of the best stands for soldering. My belief is that you shouldn’t skimp when it comes to your tools.

If there are other options out there, maybe you want to let everyone know in the comments.

Modular Soldering Station Base

The foundation for a good station is a strong base. (I know, right?) Considering your situation, which will help determine the type of base you need. I started with a permanent mounting solution but now have a totally modular soldering station.

Bolt Down

The low-profile base, model 305, was the first piece I purchased. I did, at one point, have a dedicated soldering area. In that case, I just bolted my PanaVise to the workbench. Permanent, strong and simple. I don’t have much experience with the larger model 300. I’ve been happy with the low-profile version.

The advantage of the low-profile is that once you add on a vice, your work will stay at an optimal height. The larger 300 base might offset a bit too much for comfort.

Vacuum Base Model 380 (aka Suction Cup)

Down the road, my electronics workbench became a laminated table top. For a (very) short period, a spare granite counter top in my kitchen was my work area of choice. Both of these ultra-smooth surfaces were great for the suction cup base. This base works great and gets firm adhesion, as long as the surface is smooth.

Down the road, my electronics workbench became a laminated table top. For a (very) short period, a spare granite counter top in my kitchen was my work area of choice. Both of these ultra-smooth surfaces were great for the suction cup base. This base works great and gets firm adhesion, as long as the surface is smooth.

If your surface isn’t perfectly smooth, skip this base. The pressure you put on the device being soldered will cause it to separate eventually from the table. Fortunately, the weight of the base alone is enough to hold your work in place, in a pinch.

Weighted Base Mount

My Ikea table top has a slight texture to it. This roughness renders the suction cup base virtually useless. Even with the lightest of pressure, the base disconnects.

That’s why I turned to the PanaVise Weight Base Mount Model 308. When it comes down to it, there isn’t anything special about this cast iron base. The bolt pattern fits perfectly with the low-profile bolt down base. Just bolt together and you have a reliable modular soldering station.

But… Does it work?

Yes!

The weighted base from PanaVise weighs just 5lbs (2.3kg). Honestly, at first I thought it was going to be too light. But after heavy usage (bad pun, I know), I’m pretty happy with it. Watch this AddOhm’s Let’s Build video to see it in action. I doubt you’ll ever see the PCB rock around.

Of course, if you have access to some scrap metal and a drill press, you could probably make your own base. I liked the painted cast iron, ready to go bolt pattern, and non-skid feet on the PanaVise model. Plus with Amazon Prime, it didn’t cost me extra to ship those 5 pounds.

Vise

The modular nature of the PanaVise system is one of the reasons I like it so much. There are several different clamps for various types of work. Obviously, my focus is electronics work. There are plenty of other uses for a good vise and PanaVise may have something that lets you extend your system even more.

Basic Vise

Originally I bought the bolt-down base that included this standard head, model 303. In fact, unless you want to piece together a vise system, I’d suggestion you buy a bundle with the standard head and one of the bases. For general, non-soldering, work this is a nice vise to have around.

When soldering PCBs, I found it cumbersome and overkill. Soldering large leaded (or through-hole) devices, though, worked well for this fundamental vise.

For serious electronics work, you’re going to want another option.

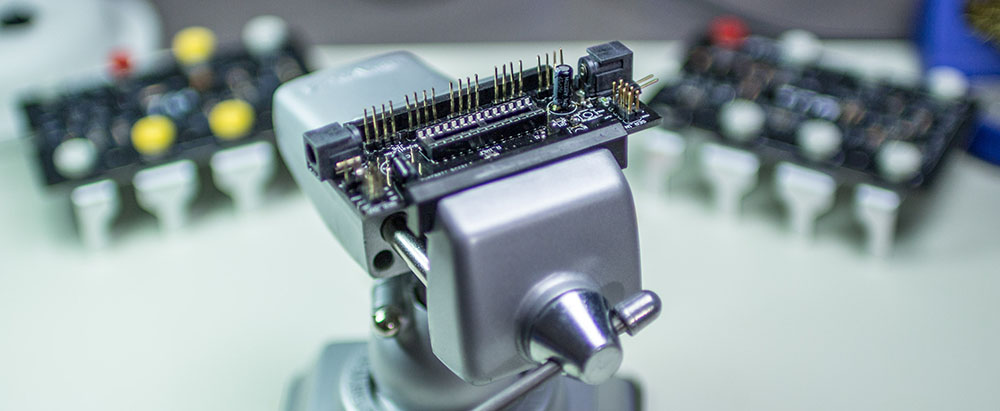

PCB Arm Vise

For the ultimate in circuit board soldering, you need the Circuit Board Holder, Model 315. It can accommodate boards up to 12in (30.5cm) wide, 0.156in (4mm) thick, and approximately 6in (15.24cm) long. I saw approximately because the board can hang off the “end” a little bit. The arms’ v-grooves provide extra stability to the inserted PCBs. Arms can be positioned anywhere on the shaft. For smaller boards, I’ll have both arms mounted on one side of the center point.

You can also check out the Model 203 and Model 366. I’ve used both just briefly, in other people’s labs. However, the 315 is what I look for when I need to get serious work done.

Conclusion

Head over to this Flickr Album for higher resolution pictures.

That is my modular soldering station. It works well in my space limited lab. In short here are the pieces I am using:

5 Comments

Hi guys, have a look at my 3D printable “PCB Workstation with Articulated Arms”:

http://www.thingiverse.com/thing:801279

It has been reviewed on makezine.com and is now available as a ready to use kit.

Nice to see you post Giuseppe, this is a very cool system.

When I’m in between prints, I work on printing another piece of mine.

I even made a time-lapse of the base printing:

https://www.youtube.com/watch?v=H-gMzyPkn7g

Hi James, I would be glad to see your finished 3D printed PCB Workstation and it would be nice also to see it at work while you are using it 😉

Several pretty cool gadgets. Great sharing.

This belongs more in a car workshop than an electronics bench (and it’s a little oily), but it’s a cost-effective tool that can be put to several uses: http://www.harborfreight.com/multipositional-magnetic-base-with-fine-adjustment-5645.html (I’m currently using it to hold a mirror – see my images in the comment section of http://www.instructables.com/id/Building-and-testing-the-optical-apparatus-from-Ti/ )