During the component shortage, I got to know Raspberry Pi’s RP2040 microcontroller. It is a dual-core Arm Cortex-M0+ with about 262 kilobytes of RAM. The feature I like most is the programmable IO pins. These are small state machines that run independently of the Arm cores. They allow for some clever tricks. For example, I used them extensively on the Mega IIe project.

Often I hear this question: “how can I get better solder joints?” Without looking at anything they are doing, I already know that they could be using more flux. Or, as I point out in this video, perhaps the correct type of flux!

Flux removes oxide layers, gets contaminants out of the way, and makes for better solder joints. But there are so many different types of flux and even more ways to apply it.

This video goes over the different types of Rosin (R, RA, RMA), Resin, Organic, and Inorganic flux. Then it shows what kind of residue gets left over. And explains why “NO Clean Flux” actually needs to be cleaned (in most cases).

What is No Clean Flux?

In the video, I make the bold statement that “no clean” is not a type of flux. I know some people will take issue with that. However, based on the IPC chart for flux bases, “no clean” is not one of them. And if you look through datasheets, you’ll find lots of variations of what manufacturers call “no clean.”

From what I can tell, “No Clean” flux is generally a Non-activated or mildly activated Rosin or Resin type. The remaining residue is non-conductive and non-corrosive. So by that general definition, many fluxes can be marketed as “No Clean.”

Using a Metcal GT120, we look at three ways to improve your soldering skills. Using flux, setting a correct temperature, and selecting the proper tip all result in better solder joints. See how well the GT120 works while learning (or reviewing) some basics to improve your soldering skills.

This episode was sponsored by Metcal.

Low-temperature solder paste makes it easier to reflow-solder and re-work surface mount circuit boards. MG Chemicals offers a Bismuth-based paste that works great from larger passive components to fine pitched packages, like QFN. In this video, learn what solder paste is, what it means for a paste to be “low temperature,” and some things to watch out for when using it.

This episode was sponsored by MG Chemicals.

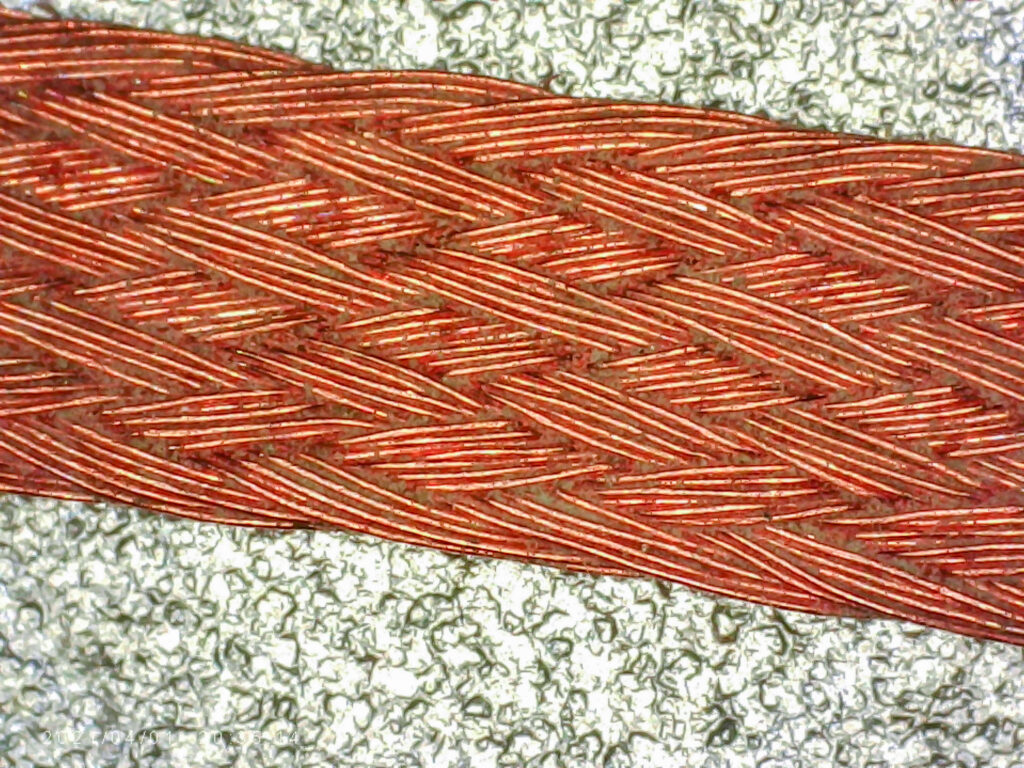

Desoldering braid removes surface solder from a circuit board. It makes reworking PCBs easy and quick. With a few tips and tricks, products like MG Chemical’s Superwick can work like magic. You can remove solder from surface mount parts, wick away excess solder blobs, and repair boards using it. In this video, James shares tips and tricks from the element14 community for using desoldering braid. (Please note: the makers of Superwick, MG Chemicals, sponsored this video)

One of my favorite shots in the entire episode is one of the microscope pictures. I often write a draft script of what I want to cover before I shoot all of the overhead video clips. In my notes, I wrote, “microscope to see the flux–can you even see it?” Imagine my surprise when I looked at Superwick under the microscope and could clearly see the flux on it.

This episode was sponsored by MG Chemicals