The Open Vapors project has taken some big steps forward recently. The controller’s enclosure is now a custom box, has a front panel, and the LCD’s menu system is almost done.

The next stage of the reflow oven project is moving to a custom PCB for the controller electronics. Overall the board is based on the ATmega32u4 with a DS3231 RTC. The LCD module is intended to be driven by one of Adafruit’s Serial backpacks. There is an area of LED indicators (something I learned from a previous project) and some extra VCC/GND pins sprinkled about.

One of the projects I really wanted to get back to when I joined the Austin TechShop was my Reflow Oven based on a Toaster Oven. The first prototype I made was a mess of AC wiring boxes with an Arduino sitting on the side. While the oven did work, it was far from pretty. Making use of the laser cutter, large workspaces, and friendly members at TS Austin, I was finally able to put together my 2nd prototype.

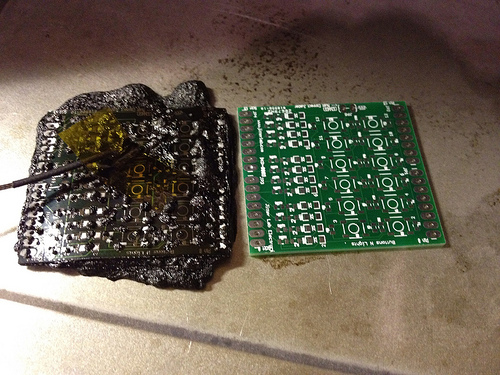

While testing my Toaster Oven’s maximum temperature I learned a valuable lesson. Soldermask has a pretty limited lifetime when it is exposed to temperatures above 250C. Looks like I need to spend some time building a temperature profile and not just brute forcing.

Build description here: Open Vapors Reflow Oven Controller Project Page

Last Updated: 2017-SEP-07

Status: Completed

[youtube id=EIHeH-U6yuY]