‘Very nice’ graphene grown on silicon carbide

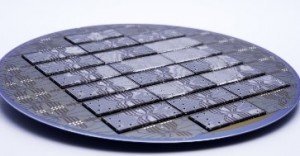

Researchers at Georgia Tech have discovered a technique for growing what they describe as “high quality” graphene on the surface if silicon carbide wafers.

Almost perfect graphene can be flaked from the surface of natural graphite, but researcher are struggling to grow anything approaching that quality on a substrate by methods compatible with chip making.

One possible method is to heat a SiC wafer to drive silicon from its surface, leaving carbon in the form of graphene.

“The basic principle requires heating the material to about 1,500°C under high vacuum. But uncontrolled evaporation of silicon can produce poor quality material, useless to designers of electronic devices,” said the university.

To improve quality, Professor Walt de Heer is heating the wafer in a closed box to keep the local atmosphere ‘humid’ with silicon molecules which controls the vapour pressure at the surface – calling the technique ‘confinement controlled sublimation’.

“For growing high-quality graphene on silicon carbide, controlling the evaporation of silicon at just the right temperature is essential,” said de Heer. “By precisely controlling the rate at which silicon comes off the wafer, we can control the rate at which graphene is produced. That allows us to produce very nice layers of epitaxial graphene.”

In the experiment, a 10x10mm wafer is heated in a graphite box with a small hole in it, either in a vacuum or in argon.

“This technique seems to be in-line with what people might one day do in fabrication facilities,” de Heer said. “We believe this is quite significant in allowing us to rationally and reproducibly grow graphene on silicon carbide. We feel we now understand the process, and believe it could be scaled up for electronics manufacturing.”

The discovery wasn’t exactly deliberate.

“Development of the sublimation technique arose from efforts to protect the growing graphene from oxygen and other contaminants in the furnace,” said the university. “To address the quality concerns, the research team tried enclosing the wafer in a graphite container from which some silicon gas was permitted to leak out.”

“We soon realised that graphene grown in the container was much better than what we had been producing,” added de Heer. “Originally, we thought it was because we were protecting it from contaminants. Later, we realised it was because we were controlling the evaporation of silicon.”

The technique was described this week in the Early Edition of the journal Proceedings of the National Academy of Sciences.